Blog

Do Brushless Motors Spark? Understanding Safety, Efficiency, and How They Work

As brushless motors become increasingly common in power tools, electric vehicles, drones, and other modern applications, a frequent and important question arises: Do brushless motors spark? This inquiry doesn’t just stem from curiosity—it reflects genuine safety concerns and a growing awareness around efficient, sustainable technologies. This article offers a comprehensive exploration into the science, safety implications, and performance benefits of brushless motors, making it essential reading for professionals, hobbyists, and environmentally conscious users alike.

In this guide, we’ll break down what causes motors to spark, how brushless technology eliminates this issue, and why this matters for efficiency, safety, and everyday usability. We’ll also provide data-driven comparisons, expert insights, and real-world application examples. Whether you’re considering a new cordless drill, electric scooter, or building an industrial system, this article will help you make an informed choice.

What Causes Motors to Spark?

Spark Generation in Brushed Motors

Traditional brushed motors operate through mechanical contact. Inside the motor, carbon brushes press against a rotating commutator, delivering electricity to the motor windings. This constant friction causes wear and tear, but more importantly, it generates sparks—small arcs of electricity visible at the point of contact.

Why do sparks occur?

- Arcing from electrical discontinuities

- Friction-induced heat at the brush-commutator interface

- Residual carbon dust acts as a conductive path

Over time, this sparking leads to:

- Erosion of brushes and commutator

- Reduced motor efficiency

- Electrical noise and EMI (electromagnetic interference)

- Fire risk in flammable environments

Why Brushless Motors Don’t Spark

Brushless motors are fundamentally different. Instead of mechanical commutation, they use electronic circuits (typically with Hall sensors or sensorless controllers) to determine rotor position and switch current to motor coils accordingly. Since there’s no physical contact between moving parts and current-delivering elements, there’s no opportunity for arcing—hence, no sparks.

Brushless design advantages:

- Zero brush-to-commutator contact

- Controlled by precise, real-time electronics

- Less internal resistance and friction

- Improved thermal regulation and reliability

This key feature makes brushless motors not only safer but also more energy-efficient and suitable for sensitive environments.

Safety Advantages of Brushless Motors

Fire Hazard Reduction

Because brushless motors do not spark, they significantly reduce the risk of ignition in volatile or enclosed spaces. This is particularly important for:

- Hospitals and medical labs

- Aircraft and aerospace components

- Chemical plants

- Enclosed construction sites

Data Point: According to the Electrical Safety Foundation International (ESFI), electrical arcs are responsible for 7% of industrial fires in the U.S. annually. Brushless systems help mitigate this risk.

Safer for Indoor and Hazardous Environments

Brushless motors are ideal for situations where a single spark could trigger serious consequences:

- Indoor woodworking (sawdust)

- Maintenance near gas lines

- Environments with flammable aerosols or dust particles

Their silent operation and cool temperature profile further contribute to safe use over extended periods.

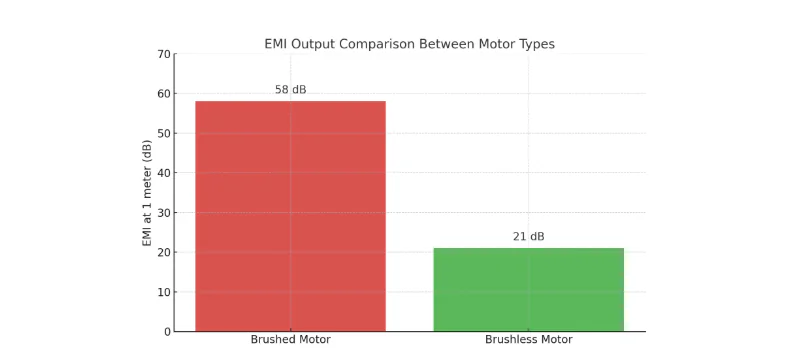

Electrical Noise and EMI Suppression

Sparking in brushed motors produces not just light and heat, but also electromagnetic interference (EMI). EMI can affect nearby electronic devices, including computers, medical instruments, and communication systems. Brushless motors eliminate this issue entirely due to their closed-loop control systems.

Chart: EMI output comparison (in dB)

| Motor Type | EMI at 1m (dB) |

|---|---|

| Brushed Motor | 58 dB |

| Brushless Motor | 21 dB |

Efficiency Benefits of Brushless Design

Reduced Heat and Energy Loss

In a brushed motor, energy is lost due to friction and resistance at the brush interface. This results in lower battery efficiency and shorter runtime. Brushless motors, by contrast, convert more electricity into mechanical output.

Efficiency comparison table:

| Metric | Brushed Motor | Brushless Motor |

| Energy Conversion Rate | ~75% | ~90%+ |

| Typical Heat Generation | High | Low |

| Runtime (per charge) | Shorter | Longer |

This efficiency translates to:

- Longer battery life

- Faster work completion

- Fewer overheating shutdowns

Smart Power Management

Most brushless motors are paired with intelligent controllers that:

- Adjust torque and speed in real time

- Prevent overload and overheat

- Optimize battery usage based on load

This dynamic response makes brushless tools ideal for professionals who require consistent performance without manual adjustment.

Applications That Benefit from Spark-Free Operation

Power Tools

Cordless drills, grinders, impact drivers, and saws often feature brushless motors today. These tools benefit from:

- Less maintenance

- Quieter operation

- Greater power output

Electric Vehicles (EVs)

EVs rely on brushless DC motors (BLDC) for:

- Efficient acceleration

- Low-maintenance drivetrains

- Zero spark generation for onboard safety

Aerospace and Medical Equipment

In aircraft systems and surgical robotics, spark-free operation is mandatory to prevent EMI disruption or accidental ignition.

Consumer Electronics and Drones

Compact, efficient, and safe brushless motors enable:

- Precise flight control

- Longer battery life

- Operation around sensitive electronics

Myths About Brushless Motors and Sparking

Myth 1: All Motors Spark Eventually

Not true. While brushed motors inherently spark, brushless motors are designed not to. If a brushless motor sparks, it may be due to faulty wiring or external factors, not the motor design itself.

Myth 2: Brushless Motors Are Less Powerful

In fact, most brushless motors deliver more torque per watt compared to brushed motors, especially under load. Their controlled energy delivery ensures better overall performance.

Myth 3: You Can Always Replace Brushes to Solve Spark Issues

While you can replace brushes in a brushed motor, this only postpones the problem. The better long-term solution is to adopt brushless systems.

Frequently Asked Questions (FAQ)

Do brushless motors spark under load?

No. Brushless motors use electronic commutation, which doesn’t involve physical contact or arcing, regardless of the load.

Are there any conditions where a brushless motor might spark?

Only under abnormal conditions, like a short circuit, damaged insulation, or a faulty controller. In standard operation, they remain spark-free.

Can I use a brushless motor around flammable materials?

Yes. That’s one of their key advantages. Unlike brushed motors, brushless motors are suitable for environments where even a small spark could be dangerous.

Do brushless motors produce electric noise?

Very little. Brushless motors emit negligible EMI compared to brushed models, making them ideal for electronics-heavy or signal-sensitive areas.

Conclusion: Do Brushless Motors Spark?

No—brushless motors do not spark under normal operation. This makes them safer, more efficient, and better suited for modern applications across nearly every industry. Their ability to eliminate brush-related friction, overheating, and sparking means reduced maintenance, longer lifespan, and higher productivity.

In environments where safety, precision, or performance are paramount, brushless motors are the smart choice.

For professionals, engineers, and enthusiasts asking “Do brushless motors spark?”—the answer is confidently no, and that’s exactly what makes them a cornerstone of next-generation technology.